Extrusion Test

Caution!

If Start G-code is incorrect, it could damage your printer. Anything which could damage your printer could cause other damage. Be absolutely sure your Start G-code is correct before printing the generated G-code.

Based on the spreadsheet introduced by this CNC Kitchen video

Use this form to generate G-code that you can use to calibrate your Extrusion Multiplier. Default values apply to standard ABS with a 0.4mm nozzle.

Press the Generate G-code button followed by Download as file to save the result.

Settings |

G-code |

||

Printer: |

|||

| Diameter of the used filament (mm) | |||

Copy the start G-code from your slicer and set the appropriate parameters. Be sure to check over the entire Start G-code every time before generating. |

|||

Copy the end G-code from your slicer and set any appropriate parameters. |

|||

| Retraction distance (mm) | |||

| Fan Speed (%) | |||

Print Bed: |

|||

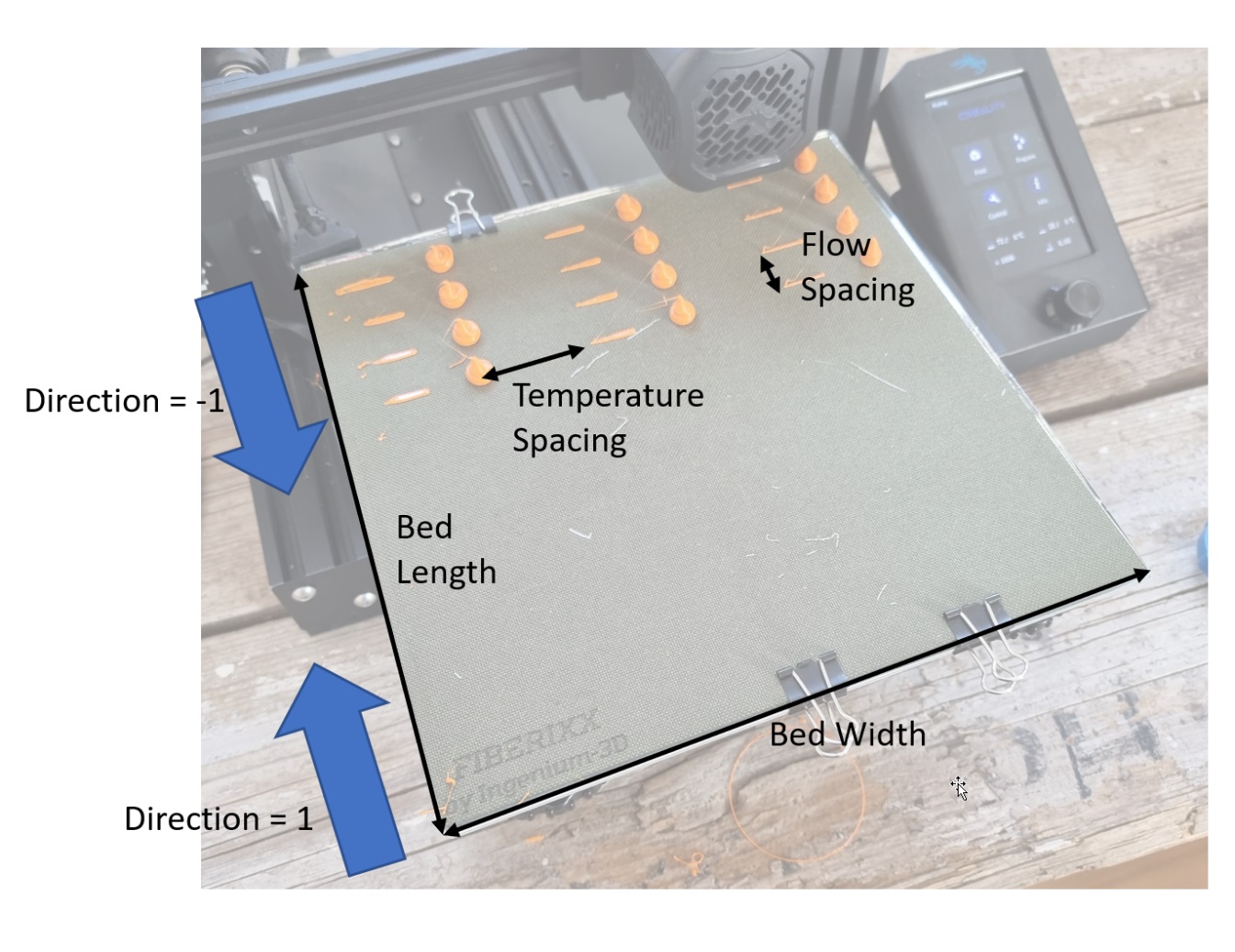

| Size (mm) of the bed in X | |||

| Size (mm) of the bed in Y | |||

| Minimum distance from edge of bed to the print | |||

Speed: |

|||

| Use mm/s instead of mm/min | |||

| Movement speed | |||

| Retract Speed of the extruder | |||

| Unretract Speed of the extruder | |||

Pattern: |

|||

| Starting value for the Flow Rate | |||

| Ending value of the Flow | |||

| Stepping of the Flow in the test pattern. Needs to be an exact divisor of the Flow Range (End - Start) | |||

| Starting value for the Temperature | |||

| Ending value of the Temperature | |||

| Stepping of the Temperature in the test pattern. Needs to be an exact divisor of the Temperature Range (End - Start) | |||

Advanced: |

|||

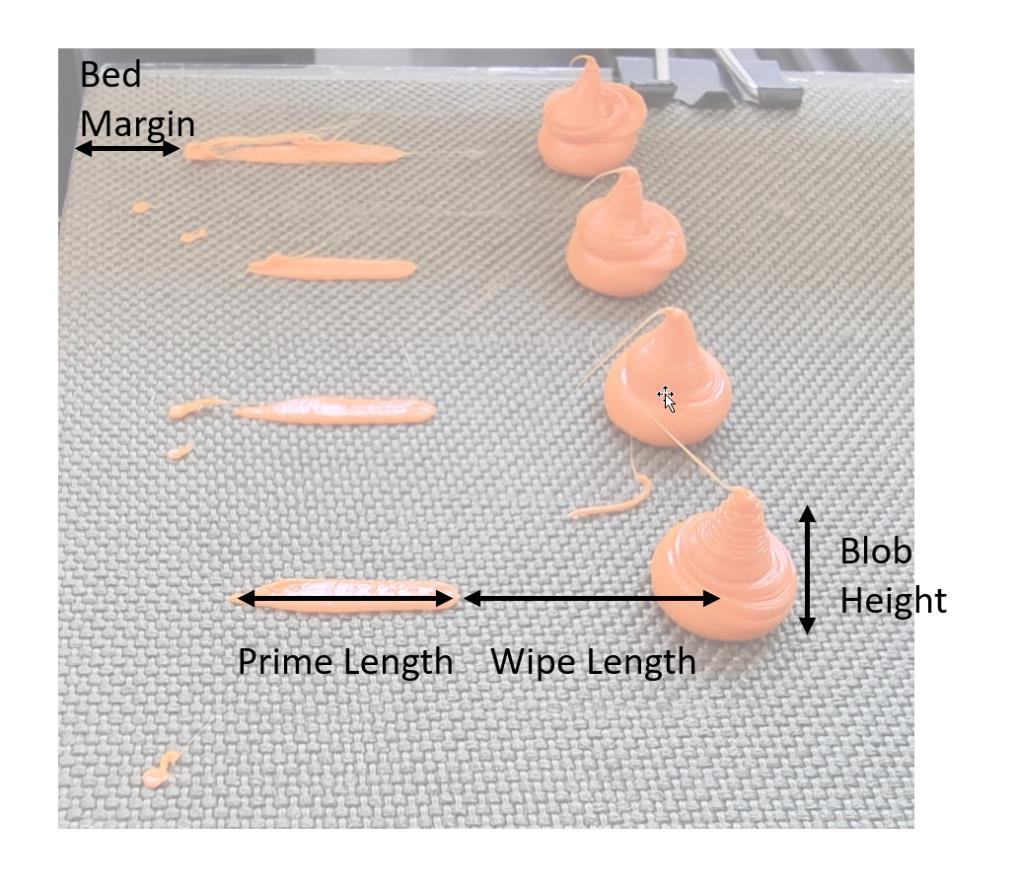

| Height of the printed blob | |||

| Length of filament to extrude into the blob | |||

| Length of the prime move | |||

| Filament to extrude during the prime move | |||

| Speed of the prime move | |||

| Distance between end of prime line and centre of the blob | |||

| Inserts a pause of x seconds before starting each prime line | |||

|

|||

Notes on the settings:

- The script checks to make sure the blobs do not collide with the toolhead. Verify it using a host software like Printrun or Repetier Host.

Start,End, andStepping Valuefor the test determines the number of rows and columns generated. For example aStart Valueof 50, anEnd Valueof 100 and aStepping Valueof 25 will create 5 rows or columns.- The proper Extrusion Multiplier depends on the filament, nozzle size, nozzle geometry and printing temperature. If any of these values change, the calibration might need to be repeated.

Images

The following images show some examples of the test patterns

Bed Settings

Print Settings